Chemische Charakterisierung und toxikologische Untersuchungen für Thermolysereaktor

Bearbeitungsnummer: TBI-V-1-262-VBW-093

Das Verhalten von Glasfaserverbundwerkstoffen (GFK), Kohlenstofffaserverbundwerkstoffen (CFK) sowie Mischungen daraus bei thermischer Belastung wird im Labormaßstab untersucht. Darüber hinaus werden Echtzeitmessungen des Produktspektrums an Thermolyseanlagen zur Verwertung dieser Werkstoffe durchgeführt. Schließlich erfolgt eine toxikologische Bewertung der festen Pyrolyserückstände über die Untersuchung der Effekte, die sie auf Lungenzellkulturen ausüben. Die Arbeiten werden grundlegende Erkenntnisse zum Produktspektrum der pyrolytischen Zerlegung liefern und direkt in die Entwicklungsarbeiten zum Aufbau einer Pyrolyseanlage für geschredderte Windenergieanlagenrotoren des Projektpartners TAB einfließen.

Background

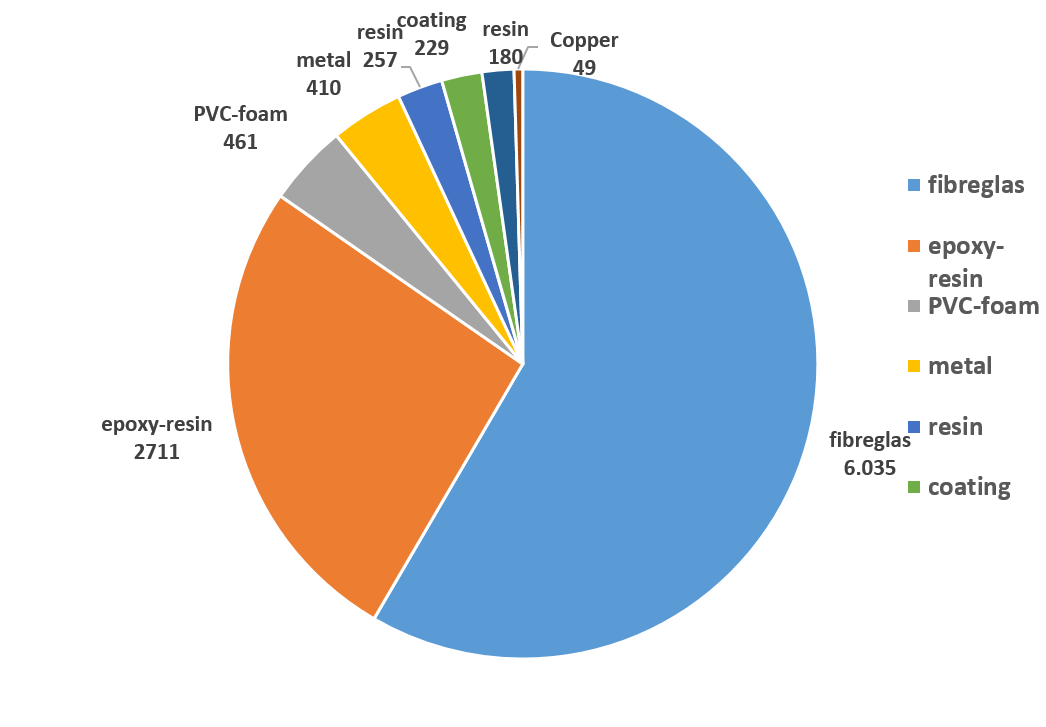

In the vein of increasing the share of regenerative sources in energy production, wind power plants play an ever-expanding role. However, there is no general solution about how to deal with the installations, especially the rotor blades, once the units are dismantled after exceeding their lifetime. The current procedure is based on separating the different components (for an average composition see figure 1) and disposing or recycling them. One important constituent of rotor blades is glass fiber or carbon fiber reinforced polymer material (GFRP or CFRP), which is after separation combusted in kilns for cement production. The question arises if there could be a better and more sustainable strategy based on material recycling of those fiber reinforced polymer materials.

Aim and first results of the project

Within the scope of the project comprises the design and construction of a new reactor for the thermolysis of glass fiber reinforced plastic and carbon fiber reinforced plastic. This part is executed by the project partner TAB GmbH. Parallel to the reactor design process, laboratory experiments are carried out to chemically characterize the feedstock material and evaluate its thermal behavior. The acquired data will help optimizing the design parameters of the reactor, especially temperature profiling. Additional data will be generated by experiments at an existing thermolysis plant, which allows access to product samples and side products such as coke and condensates. This will also include the application of modern laser mass spectrometric on-line process analytical technologies. A further concern in the recycling of fiber-containing materials is the potential inhalation toxicity of inhalable fiber dust (after WHO definition: persistent inorganic fibers with a length > 5 µm a diameter < 3 µm and a length-to-diameter ratio of > 3:1) or toxic chemicals that may occur in the in different stages of the recycling process or in the products. It is e.g. well known that carbon fibers could shrink under thermal stress to dimensions deemed critical according to the WHO definitions. For testing the products or process dusts for potential chemical or fiber toxicity in addition to chemical analyses for toxicants also in-vitro toxicological studies on human lung cell cultures will be performed and cytotoxic and genotoxic endpoints are determined.

An important parameter for the successful performance of the recycling process is the thermolysis temperature. It must be high enough to decompose and remove the organic coating material, but should be as low as possible to preserve the tensile strength of the recycled glass or carbon fibers. Thermogravimetry (TG) investigations of different feedstock materials containing GFRP revealed the majority of thermal decomposition at temperatures around 400 °C. The first results on the evolved gas analysis of the released chemical compounds during TG experiments showed bisphenol A and its pyrolysis products, typical degradation substances of epoxy resin. Investigating thermolysis products of the feedstock material from the existing plant will help to determine if all organic substances have been successfully removed during the process. With this, an optimal temperature window for the thermolysis process will be assessed for each feedstock. For the investigation of toxicological properties of the formed recyclates and solid byproducts, a novel cell culture system will be designed, assembled, and tested. It is about a triple cell culture system consisting of lung epithelial cells (A549), fibroblasts, and macrophages. Currently, the triple cell culture was successfully assembled and tested with e.g. carbon nanotubes.

Dieses Projekt wird/wurde kofinanziert von der Europäischen Union aus dem Europäischen Fonds für regionale Entwicklung. Operationelles Programm Mecklenburg-Vorpommern 2014-2020 - Investitionen in Wachstum und Beschäftigung

Project realization at University Rostock

Lukas Friederici

University of Rostock

Institute of Chemistry

Division of Analytical and Technical Chemistry

Department Life Light & Matter

Lukas Friederici

Albert-Einstein-Straße 25

18059 Rostock (Germany)

Tel.: +49 (0) 381 498 - 8978

Patrick Martens

University of Rostock

Institute of Chemistry

Division of Analytical and Technical Chemistry

Patrick Martens

Albert-Einstein-Straße 27

18059 Rostock (Germany)

Tel.: +49 (0) 381 498 - 6533

patrick.martensuni-rostockde

Arne Koch

University of Rostock

Institute of Chemistry

Division of Analytical and Technical Chemistry

Arne Koch

Albert-Einstein-Straße 27

18059 Rostock (Germany)

Tel.: +49 (0) 381 498 - 6534

arne.kochuni-rostockde

Dr. Thorsten Streibel

University of Rostock

Institute of Chemistry

Division of Analytical and Technical Chemistry

Dr. Thorsten Streibel

Albert-Einstein-Straße 27

18059 Rostock (Germany)

Tel.: +49 (0) 381 498 - 6536

thorsten.streibeluni-rostockde